You cannot deny the importance of nuts and bolts in your home, neither can you deny the importance they have in holding your tools together. However, it becomes confusing trying to find out what goes first – lock washer or flat washer?

When you get the world of washers, you cannot deny the convenience they give you when you need to repair your household tools.However, many people, including myself, become confused when attempting to use bolt, nuts, and lock washers – since the differences between the two washers is hard to tell. In fact, I really struggled to find the importance of flat washers anyway, every time I compared them to lock washers.

However, in order to understand the order of using lock or flat washers, it is important to understand why they are used, and what you need for specific tasks.

What are washers?

These a very thin plates that have a circular shape, and have holes at their center that play the role of weight distribution in a fastener like nuts or bolts. Theyalso work as springs, reducing friction, wearing pads, and as spacers to prevent galvanic corrosion by insulating screws from aluminum surfaces.

They are usually made from plastic or metal, although you will also find fiber or rubber ones – especially in valves or faucets.

What is their importance?

Even though flat and lock washers are both washers and have similar designs overall, their purposes are actually different. When you use them incorrectly, they can lead to injury or damage to your equipment, so it is actually important to understand why they are used.

When you want to increase the surface area of a surface so that force is distributed more evenly when you tighten a fastener, you use a flat washer. On the other hand, lock washers are more useful when you want to increase tension when you are tightening something, so that the nuts or bolts do not come loose after you are done.

What are the varieties of washers?

Believe it or not, you can get a variety of lock and flat washer types. For instance, flat washers can come in SAE (Society of Automotive Engineers), USS (United States Standard), and common flat, as well as dock washers and fender washers. As for lock washers, you can get them in the high-collar lock or common lock varieties.

Main features to pay attention to

These washers can come in a variety of thicknesses and diameters, both external and internal. They also come in a variety of materials, such as chrome, stainless steel, galvanized steel, and rubber.

Depending on their composition and size, they can be useful for a variety of purposes. For instance, a silicon bronze washer is good for marine activities (since it is not prone to rusting or corrosion). Galvanized and zinc plated steel gives high protection against rusting. Stainless steel is for areas that are seen frequently due to their attractive high gloss finish.

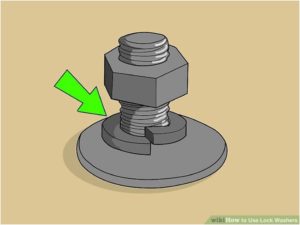

Lock washers have a unique feature that sets them apart from a flat washer though – their ‘teeth’. Because their teeth are on the outer surface, they are better when you want a bolt or nut to go on them without straining to keep it in place – however, they resist coming off when you try to unscrew them. While this is a good thing for holding components together, they can damage your surfaces when you put them first. Therefore, you should attach them after installing flat washers.

For a summarized procedure of fastening a lock washer, follow these steps:

- Under the threaded fastener, place the lock washer. This will hold the threaded faster or nut you are using in their place. However, if your project involves you attaching other elements of your hardware, always install them before you add the lock washer. Remember, the aim of the lock washer is to hold all the elements in place.

- Ensure the washer itself holds tightly against the other surface – in fact, it should press against the adjacent surface and the nut or fastener. If you are fastening a lock nut, it is very important to take care of this aspect.

- Using a wrench, tighten the nut clockwise until it stays firmly in place (if doing a small household job), or use a torque wrench if dealing with larger projects.

Conclusion

While both of these washers look similar, their functionality is quite different. Flat washers prove more useful when you are spacing objects, especially when a bolt is too long to do the job properly. Lock washers are usually used when the application involves vibration, as the nuts and bolts can come loose over time.For that reason, a flat washer should come first, then the lock washer keeps all components steady.

FAQs

Which side of the washer does down?

While there is no specific rule that states which sides goes up or down, it is better to put the blurred side down.

Do I put the washer on the nut or bolt?

This will depend on the number of washers you have. If it is only one, the washer will be on the side of the nut because of less surface area in contact with the adjacent surface being connected.

Can I re-use a lock washer?

This will depend on the application, as well as the bolt’s hardness. For instance, a stainless steel washer must be replaced after single use, while other washers can be re-used multiple times.

Are washers even necessary?

Yes, as they protect the surfaces of your assembled parts and prevent them from loosening and coming off.

What side does the lock washer face?

For the jagged side, it should be towards the nut, as you are preventing it from unscrewing itself.